FRAMES MANUFACTURING

WELDING

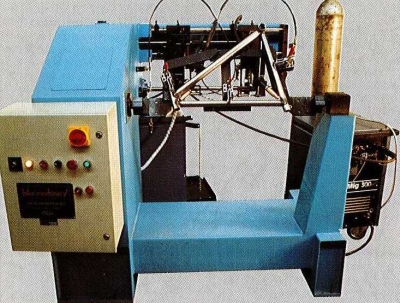

PEGASUS

AUTOMATIC DOUBLE TORCH MIG MAG WELDING

The tube/tube welding of the frame front quadrilateral is usually completed in three different phases:

- Bottom bracket to seat tube (one weld)

- Down tube to bottom bracket and head tube (two welds)

- Top tube to seat tube and head tube (two welds).

The machine can be adapted for the three operations described above by using different holding templates and cams, shaped exactly according to the weld outline. Each torch (two) is movable, controlled by the cams. A fourth option for machine use is fork head welding by equipping the machine with the appropriate equipment. The frame parting occurs as follows: the parts to be welded are inserted in the holding template (on the machine) and secured by the appropriate manual clamps. Un pressing the push button, the template (with the frame) starts to rotate, while the welding torches, controlled by the cams, follows the welding joint outline until the cycle is completed. At the end of the cycle the template returns to the starting position to allow unloading the piece and loading a new one. The torches are mounted on transverse carriages which allow a horizontal movement at the weld starting point to allow completion of the welding circumference. On request the machine revolves more than 360° for weld overlap. The torches are equipped with swinging devices so that they position themselves optimally with respect to the welding area.